Ub 914*419*388 UC 356*406*393 Hea Heb Hem 150 Hot Rolled Welded H Beams

Product Detail

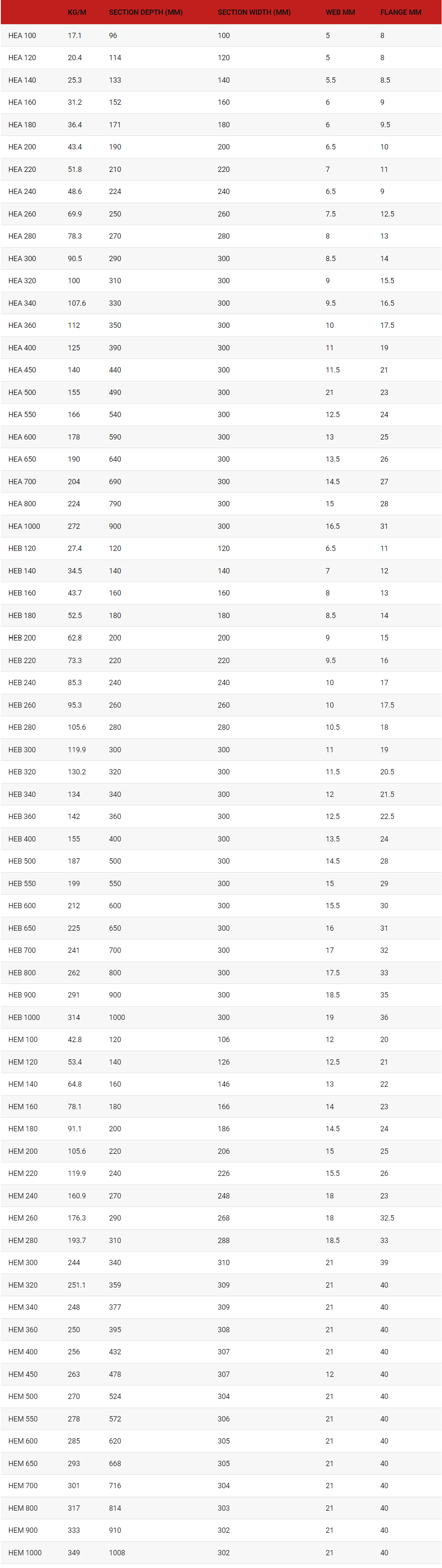

These designations signify different types of IPE beams based on their dimensions and properties:

- HEA (IPN) beams: The HEA beam is a lightweight type of the "A" class within the European standard series of H-section steel (HE series). Its H-shaped cross-section combines lightweight design with foundation load-bearing requirements, making it commonly used in small and medium-sized building structures.

- HEB (IPB) beams: The HEB beam is a medium-sized "B" type in the European standard HE series H-beam. Its cross-section is symmetrical and H-shaped, offering balanced mechanical properties and balancing load-bearing capacity with stability. It is widely used in medium-load structures such as industrial plants and medium-sized bridges.

- HEM beams: The HEM beam is a heavy-duty, thick-walled version of the European standard hot-rolled H-beam series (compliant with EN 10034). Its web and flange are significantly thicker. "HEM" stands for "haute efficacité mécanique" (French for "high mechanical efficiency") and has an extremely high section moment of inertia.

These beams are designed to provide specific structural capabilities, choose the right product based on your needs.

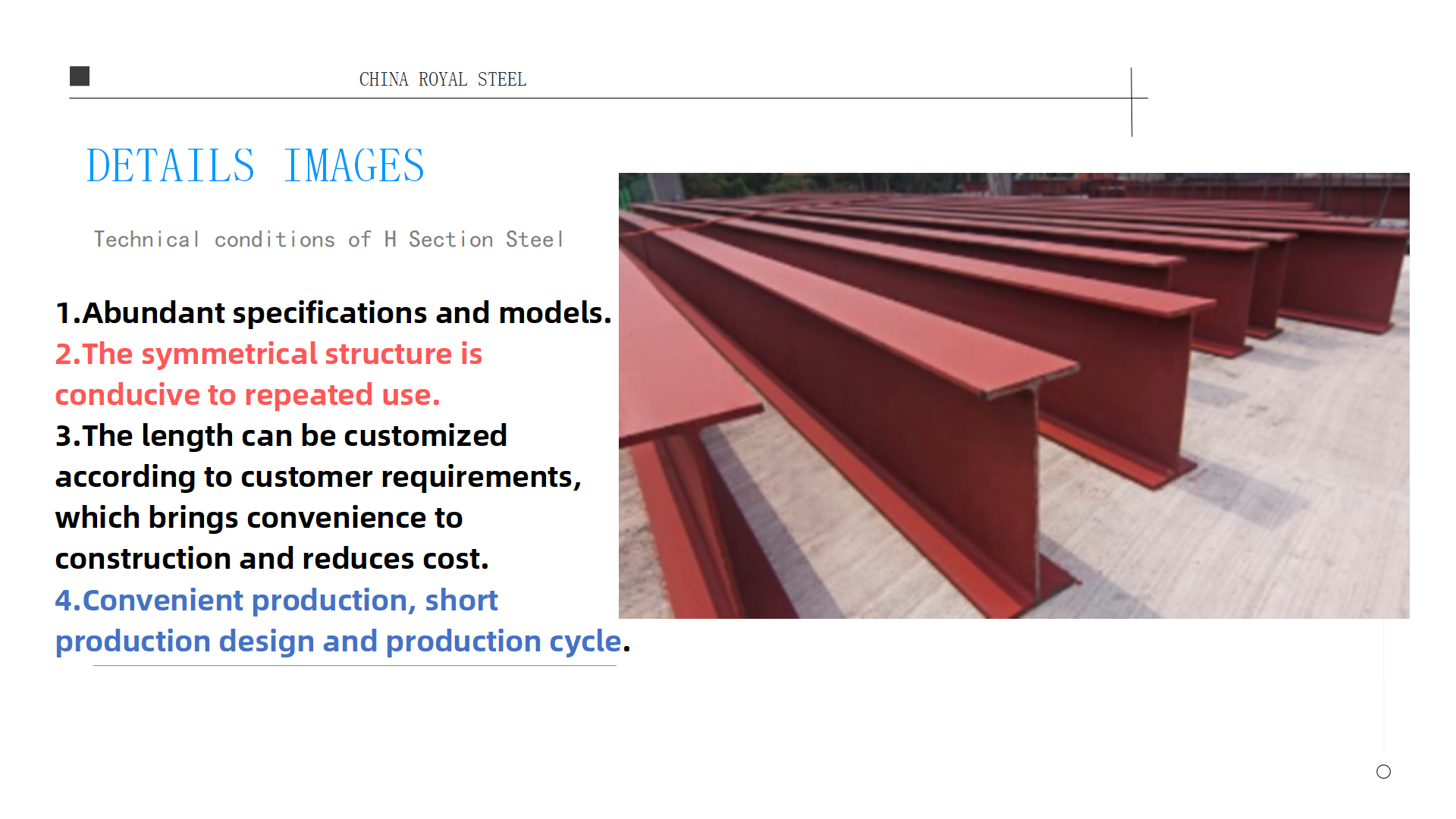

Features

HEA, HEB, and HEM beams are European standard IPE (I-beam) sections used in construction and structural engineering. Here are some of the key features of each type:

HEA (IPN) beams:

Lightweight cross-section

High material utilization

HEB (IPB) beams:

Standardized cross-sectional dimensions

Rational material distribution

HEM beams:

Significantly thicker web and flange thicknesses

Extremely strong cross-sectional moment of inertia and load-bearing capacity

These beams are designed to meet specific structural requirements and are selected based on the intended use and load-bearing needs of a building or structure.

Application

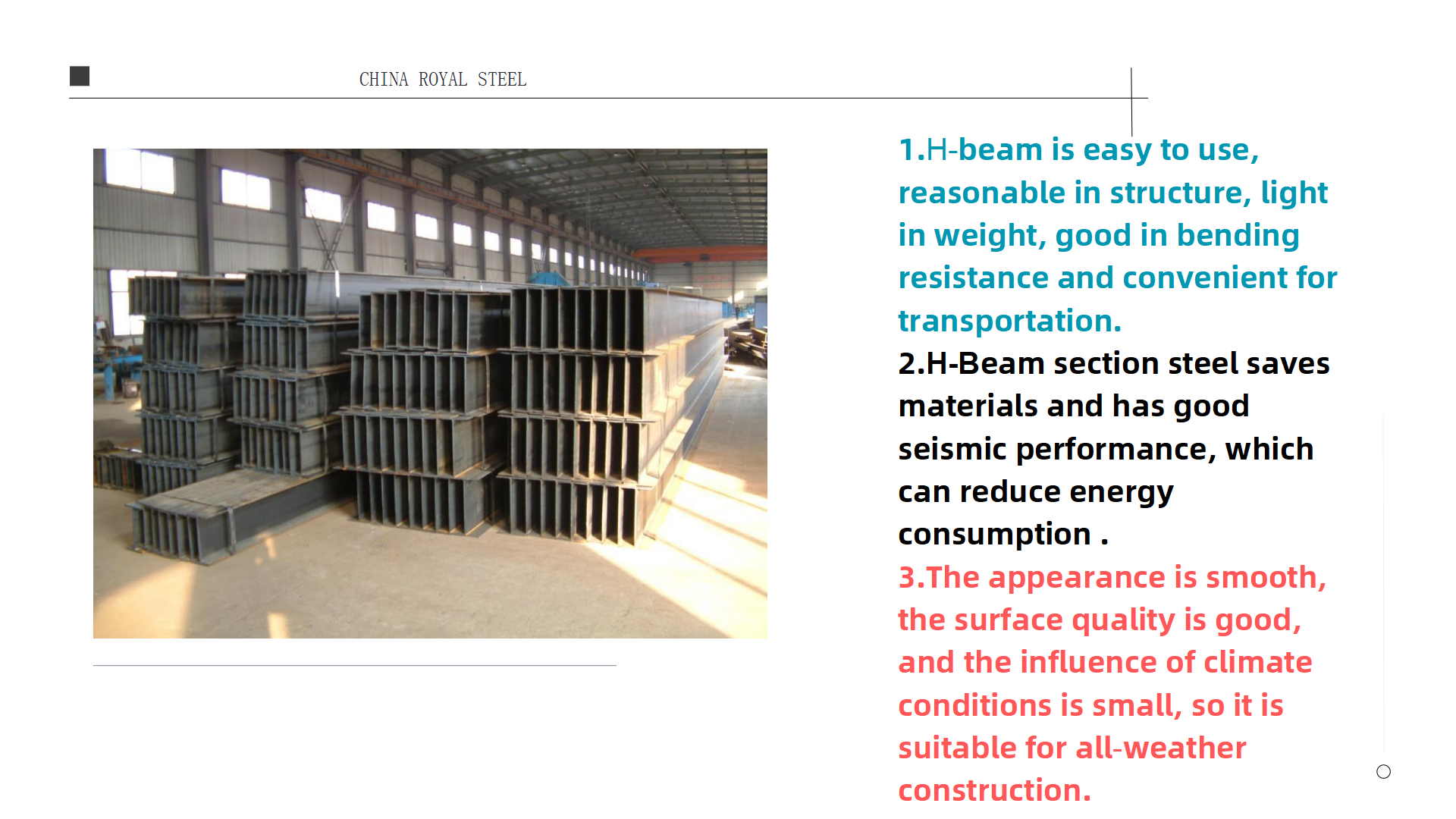

HEA, HEB, and HEM beams have a wide range of applications in the construction and structural engineering industries. Some common uses include:

1. HEA beam (lightweight H-beam): Suitable for low-load and lightweight applications.

The core advantages are light weight, high material utilization, and easy installation. Its mechanical properties meet foundation load-bearing requirements, eliminating the need to bear extreme loads. Its main applications are:

Civil buildings: secondary beams, partition wall keels, and balcony frames in multi-story residential buildings/apartments;

2. HEB Beam (Medium H-Beam): Suitable for general medium-load scenarios

The core advantages of HEB beams are balanced mechanical properties (moderate bending and shear resistance), strong versatility, and high cost-effectiveness. They lie between the lightweight design of HEA beams and the heavy-duty design of HEM beams. They are the most commonly used type in construction and infrastructure, with primary applications in:

Industrial and commercial buildings: Main beams/columns for medium-sized factories, load-bearing frames for multi-story office buildings, and main load-bearing beams for supermarkets and warehouses;

3. HEM beam (Heavy Duty H-Beam): Suitable for high loads and extreme working conditions

The core advantages of HEM beams are thick webs/flanges, large cross-sectional moments of inertia, and extremely high load-bearing capacity. They can withstand large bending moments, high axial forces, and complex loads (such as impact and vibration). They are primarily used in:

Heavy industrial facilities: Main beams/columns in heavy machinery plants (such as shipyards and metallurgical plants), support frames for steelmaking blast furnaces, and foundations for heavy equipment (cranes and rolling mills);

Packaging & Shipping

Packaging and Protection:

Packaging is crucial to maintaining the quality of ASTM A36 H-beams during transportation and storage. Use high-strength strapping or ties to securely bundle the material to prevent movement and potential damage. Additionally, take steps to protect the steel from moisture, dust, and other environmental factors. Wrapping bundles in weather-resistant materials such as plastic or tarpaulin helps prevent corrosion and rust.

Loading and securing for transportation:

Loading and securing the packaged steel onto the transport vehicle should be done carefully. Employing suitable lifting equipment, such as forklifts or cranes, ensures a safe and efficient process. The beams should be evenly distributed and properly aligned to prevent any structural damage during transportation. Once loaded, securing the cargo with adequate restraints, such as ropes or chains, guarantees stability and prevents shifting.

FAQ

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.