Unmatched Strength Light Weight Prefabricated Steel Structure Warehouse Workshop Building

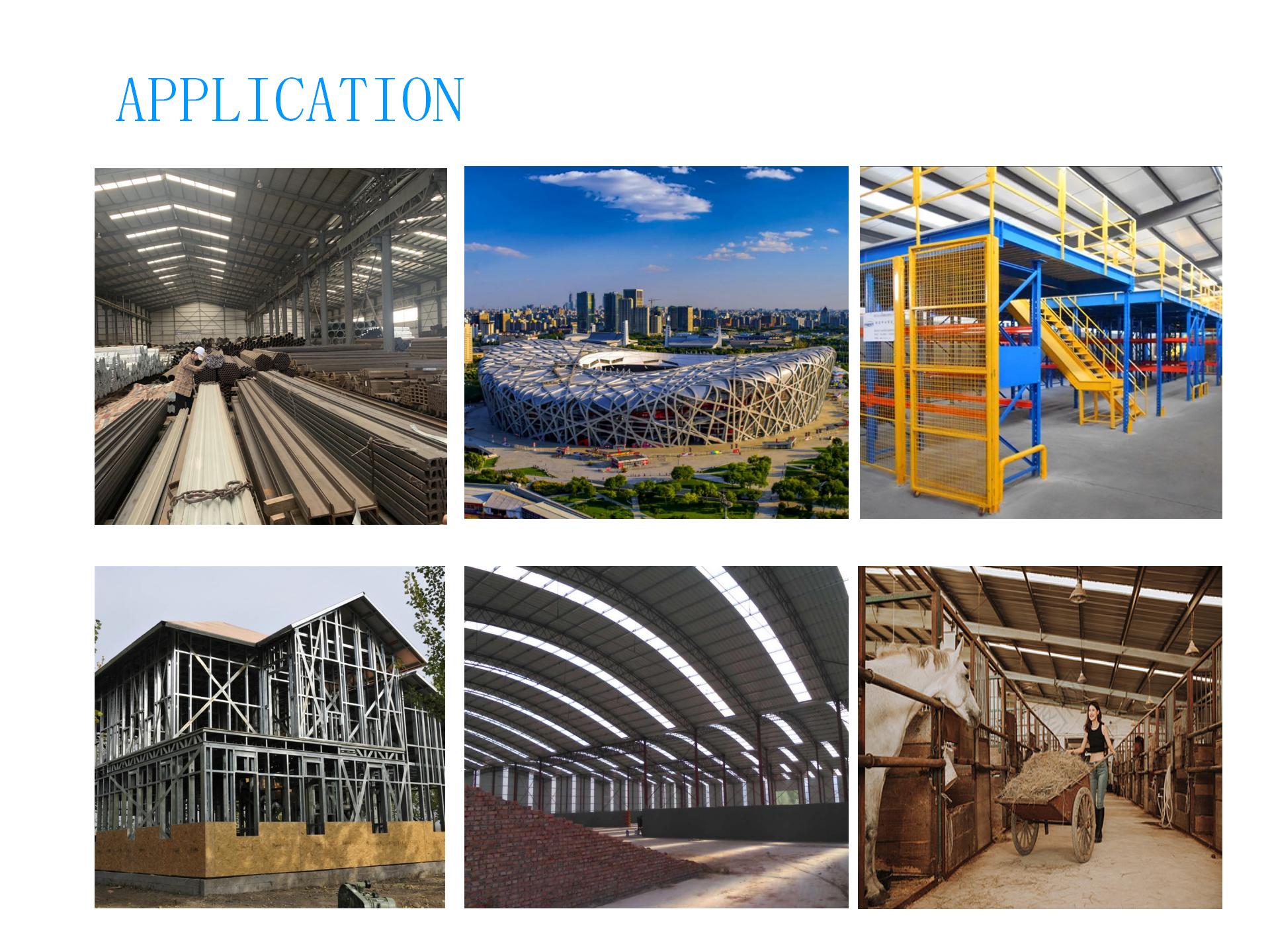

Steel Structure are widely used in various building types and engineering projects, including but not limited to the following aspects:

Commercial buildings: such as steel school buildings, shopping malls, hotels, etc., steel structures can provide large-span, flexible space design to meet the space needs of commercial buildings.

Industrial: Robust factory, warehouse and energy applications.

Commercial Buildings Offices, malls, exhibition centers and stadiums; Customizable space and rapid lead time.

Public Infrastructure: Bridges, railway and airport terminals, ports; capacious and long-span.

Residential Buildings: Steel frame houses and flats: light, earthquake resistant and sustainable.

Special & Temporary Structures: skyscrapers, tanks, pavilions and modular offices; adaptable, easy to construct and relocate.

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.steel sheet corrugated ; 2.sandwich panel made of rockwool ; 3.EPS panels sandwiches ; 4.sandwich panel with glasswool |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

Prevention what is the prevention when building the steel house?

1.Check if it is a sound structure

The arrangement of rafters in a steel house should be consistent with the configuration of the design and renovation of the loft. Second, care should be taken during processing, be sure not to hurt the steel, steel second injury easy to cause safety hazards.

2.Pay attention to the choice of steel materials

There are many types of steel available in the market but not all of then suited for house building. For the stability of structure, hollow steel pipe is not suggested, and don't paint the inside directly, because it will rust.

3.Keep the structural layout clear

Steel structures will vibrate more intensely when they begin to be loaded. So, accurately analysis and calculation are needed to control the vibration while achieving good look and satisfying strength.

4.Attention to Paint

When the steel frame is welded in its entirety, the finished surface should be dusted with anti-rust paint, so as not to rust under the external conditions. Rust not only influences the decorative effect of walls and ceilings but also has the possibility to become a safety hazard.

DEPOSIT

The construction of Steel Structure Factory buildings is mainly divided into the following five parts:

1. Embedded components (to stabilize the factory building structure)

2. Columns are typically made of H-shaped steel or C-shaped steel (typically two C-shaped steels are connected with angle steel).

3. Beams are typically made of C-shaped steel or H-shaped steel (the height of the center section is determined by the span of the beam).

4. Rods, typically C-shaped steel, but can also be channel steel.

5. There are two types of tiles. The first is single-piece tiles (colored steel tiles). The second is composite panels (polystyrene, rock wool, polyurethane). (Foam is filled between the two layers of tiles, providing warmth in winter and coolness in summer, while also providing sound insulation.)

PRODUCT INSPECTION

Steel structure precast engineering inspection mainly involves raw material inspection and main structure inspection. Among the steel structure raw materials that are often submitted for inspection are bolts, steel raw materials, coatings, etc. The main structure is subjected to weld flaw detection, load-bearing testing, etc.

Examination Range Materials:

Steel, welding materials, coating materials, standard fasteners, bolts, sealing plates, cone heads, sleeves.

Fabrication & Assembly: Steel component processing and pre-assembly dimensions, single-layer, multi-layer, high-rise, and steel grid structure installation dimensions.

Connections & Welding: Welding projects, roof bolt welding, ordinary and high-strength bolt connections, installation torque.

Coating: Steel structure coating thickness and uniformity.

Inspection items:

Visual & dimensional Are the geometric dimensions, the structural verticality and the accuracy of assembly as intended.

Mechanical and material properties Tensile, impact, bending, pressure-bearing, stiffness, strength and stability; metallographic morphologic structure and chemical composition.

Weld Quality: Non-destructive Examination, internal/external weld defects, mechanical properties of weld seam.

Fasteners: Strength, final tightening torque, connection integrity.

Coating & corrosion: thickness, adhesion, uniformity, abrasion, salt spray, chemical, moisture, heat, weather, temperature resistance, cathodic stripping.

Special tests: Ultrasonic and magnetic particle flaw detection, mobile communication steel tower mast inspections.

PROJECT

Our company often exports Steel Structure Workshop products to the Americas and Southeast Asian countries. We realized an American project of 543,000 m² with 20,000 tons of steel, developing a complex steel structure for production, living, offices, education and tourism.

APPLICATION

1. Cost Savings: Steel structures have lower production and maintenance costs, and 98% of components can be reused without losing strength.

2. Fast Installation: Precisely fabricated components speed up assembly, supported by management software for efficient construction.

3. Safety & Health: Factory-made components allow safe on-site assembly with minimal dust and noise, making steel structures one of the safest building solutions.

4. Flexibility: Steel structures can be easily modified, extended, or reinforced to meet future needs that other building types cannot achieve.

PACKAGING AND SHIPPING

Packing: Customized to your requirements or optimized for best protection and transport.

Shipping:

Mode of Transport:Pick up flatbed truck, container, ship based on the steel structure’s weight, quantity, distance and rule.

Materials Handling: Handle with cranes, forklifts, or loaders of sufficient capacity to load and unload safely.

Load Security,: Strap and brace the steel pieces to stop movement and damage in transportation.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

Scale Advantage: Having a large steel mill and supply chain, we are able to produce at scale and logistics scale, providing steel production and service one-stop solutions.

Product Variety: We offer a series of products such as steel structure,rail,sheet pile,photovoltaic bracket,channel steel and silicon steel coil,providing flexible solutions to diverse demands.

Stable Supply: Stable production line and supply chain guarantees the delivery, especially in large quantity.

Brand Influence: Strong market presence, well-known brand.

Complete service: customized production transportation full-service.

Price Advantage: Professional Manufacturer Direct from Factory with good quality steel products at reasonable and competitive value.

*Send the email to [email protected] to get a quotation for your projects

COMPANY STRENGTH

CUSTOMERS VISIT