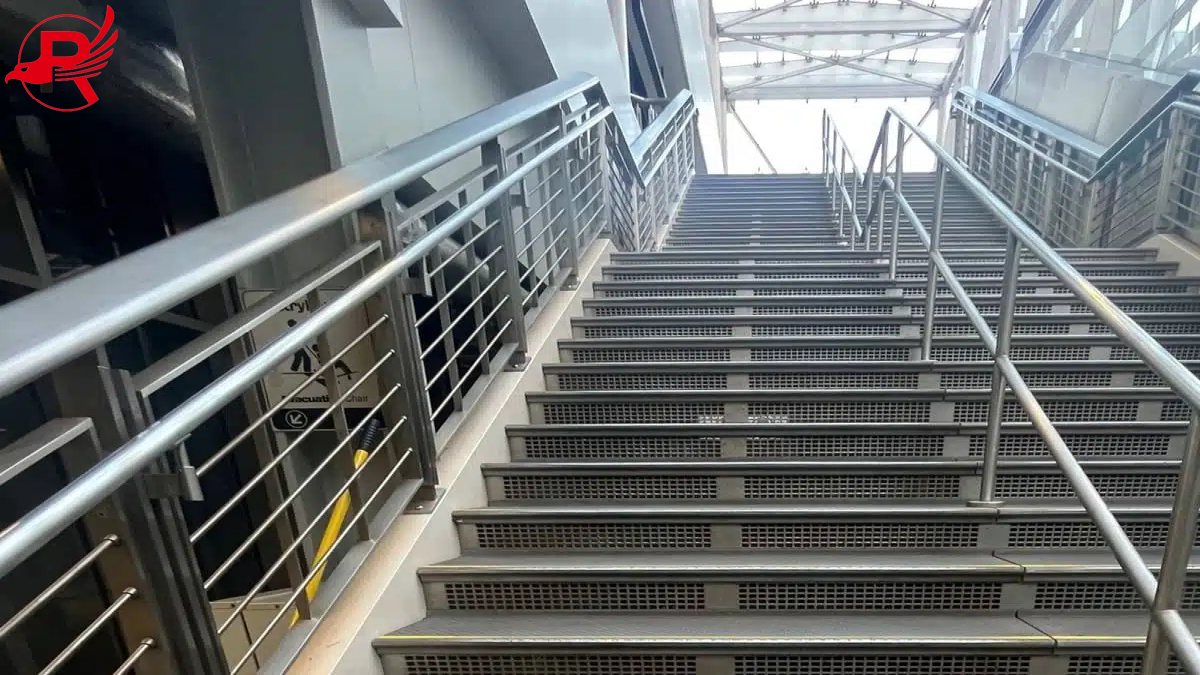

ASTM A572 Grade 50 Steel Stair Case Indoor or Outdoor Prefabricated Metal Staircase

Product Detail

| Parameter | Specification / Details |

|---|---|

| Product Name | ASTM A572 Steel Stair / High-Strength Industrial & Commercial Staircase |

| Material | ASTM A572 Structural Steel (Grade 50, optional Grade 42 or 55) |

| Dimensions | Width: 600–1200 mm, Step Rise: 150–200 mm, Step Depth: 250–300 mm, Length: 1–6 m per section (customizable) |

| Type | Prefabricated / Modular Steel Stair |

| Surface Treatment | Hot-dip galvanized; optional epoxy or powder coating; anti-slip treads |

| Mechanical Properties | Yield Strength ≥345 MPa, Tensile Strength 450–620 MPa |

| Features | High strength, modular design for fast installation, anti-slip treads, suitable for heavy-duty and outdoor use |

| Applications | Industrial plants, warehouses, commercial buildings, infrastructure projects |

Conventional Surfaces

Galvanized Surfaces

Spray Paint Surface

ASTM A572 Steel Stair Size

Free-standing provide safe, secure support for operators in factories and warehouses, allowing use on floors, platforms and machinery.

Can be used on main or secondary staircases in offices, shopping centres and hotels. Modern and safe solution for high-traffic areas.

Great for condos, duplexes and other multi-level dwellings, with a variety of sizes and finishes to meet your spatial and design requirements.

| Stair Part | Width (mm) | Height/Rise per Step (mm) | Step Depth/Tread (mm) | Length per Section (m) |

|---|---|---|---|---|

| Standard Section | 600 | 150 | 250 | 1–6 |

| Standard Section | 800 | 160 | 260 | 1–6 |

| Standard Section | 900 | 170 | 270 | 1–6 |

| Standard Section | 1000 | 180 | 280 | 1–6 |

| Standard Section | 1200 | 200 | 300 | 1–6 |

ASTM A572 Steel Stair Customized Content

| Customization Category | Options | Description / Range | Lead Time | Inspection |

|---|---|---|---|---|

| Dimension | Width (B), Step Height (R), Tread Depth (T), Stair Length (L) | Width: 600–1500 mm; Step Height: 150–200 mm; Tread Depth: 250–350 mm; Length: 1–6 m per section | 7–15 days (standard); 15–30 days (custom sizes) | Dimensional check, step height & tread depth verification |

| Processing | Drilling, Hole Cutting, Prefabricated Welding, Handrail Installation | Steps and stringers can be modified; handrails and guardrails pre-installed | 10–20 days depending on complexity | Conformity with drawings, welding quality, hole position accuracy |

| Surface Treatment | Hot-Dip Galvanized, Epoxy, Powder Coating, Anti-Slip Finish | Coatings selected for indoor/outdoor use, corrosion resistance, or slip prevention | 10–20 days depending on coating type | Coating thickness, adhesion, visual surface inspection |

| Marking & Packaging | Custom Labels, Project Info, Shipping Method | Project-specific labeling; packaging suitable for container, flatbed, or local transport | 3–7 days | Label accuracy, bundle integrity, protection for transport |

Surface Finish

Application

1.Industrial Facilities

Used in factories and warehouses to access floors, platforms and machinery and tools, the free-standing or wall-mounted aluminum ladders provide a safe, secure and reliable support to bear the heavy load of the operators.

2.Commercial Buildings

Can be used on main or secondary staircases in offices, shopping centres and hotels. Modern and safe solution for high-traffic areas.

3.Residential Projects

Great for condos, duplexes and other multi-level dwellings, with a variety of sizes and finishes to meet your spatial and design requirements.

Our Advantages

1.We utilize high quality steels such as ASTM A572 and more, making ours strong, durable and built to last.

2.Size, coating, processing and prefabrication can be customized toyour project needs.

3.Employing modular construction design concept and good logistics management, we guarantee delivery on schedule anywhere in the world.

4.All products are certified to international standards and are designed to be anti-slip, corrosion-resistant and load-tested.

5.We offer full project support from technical advice, OEM customization to packing and shipping solutions .

6.Reliable industrial clients worldwide.

*Send the email to [email protected] to get a quotation for your projects

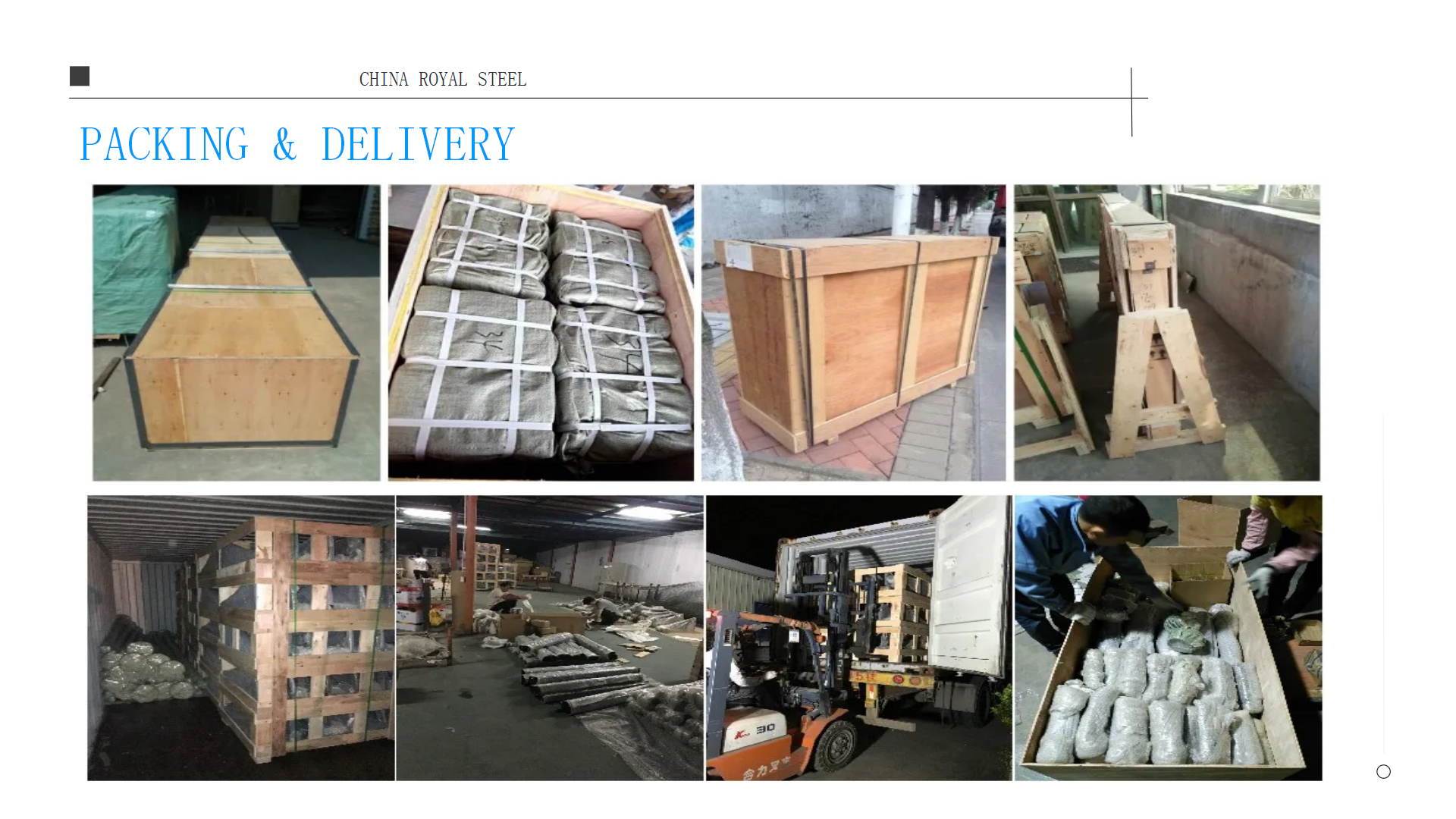

Packaging & Shipping

Packing

Packaged with Steel Straps: beams and stairs components are firmly bundled to avoid shifting.

Wooden Supports/ Blocks: Used between layers to prevent bowing or warping.

End Protection: Edges are protected (plastic or wood caps) from damage while shipping.

Rust Protection: Oiled, epoxy-coated or wrapped to prevent rust for long distance or sea shipping.

Custom Packing: Water proof wrapping, palletizing, or container specific loading can be arranged upon request.

Delivery

Port-to-Port Shipment: Loading the containers securely for international shipping.

Direct Site Delivery: Delivery by truck to job site for quick install.

Project-Based Logistics: Combined shipment for multiple beam sizes or for multiple runs of a similar design.

Lead Time: Stock items shipment 7-15 days, customized orders 15-30 days.

Urgent Orders: Rush delivery service are available on request.

FAQ

Q1: What standards are your products complying with?

A1: ASTM A36, A572 Grade 50, and comparable EN/JIS/GB standards.

Q2: Can we change size or design?

A2: Yes, width, height, tread depth, length, handrails and module design are available.

Q3: What kinds of surface treatment can I apply?

A3: Hot-dip galvanized, epoxy, powder coated and anti-slip coating.

Q4: What is the packing method of products?

A4: Strapped in bundles with wooden supports,end caps,rust protection optionally.