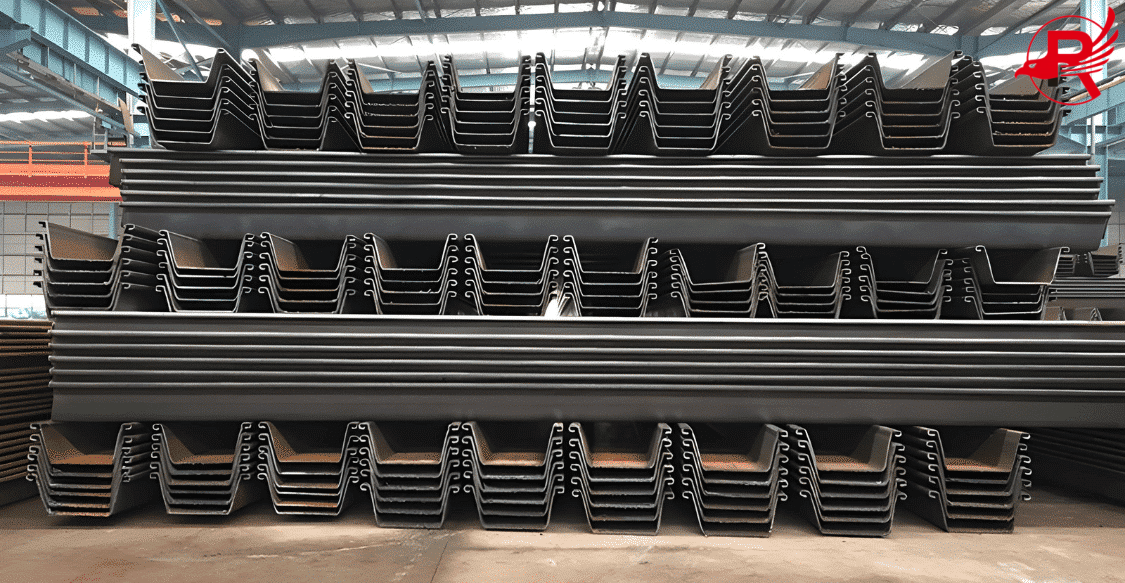

Cold Formed EN 10025 S235 / S275 / S355 6m-18m U-shaped Steel Sheet Pile

| Steel Grade | EN 10025 S235 / S275 / S355 |

| Standard | EN 10025 |

| Delivery time | 10~20 Days |

| Certificates | ISO9001,ISO14001,ISO18001,CE FPC |

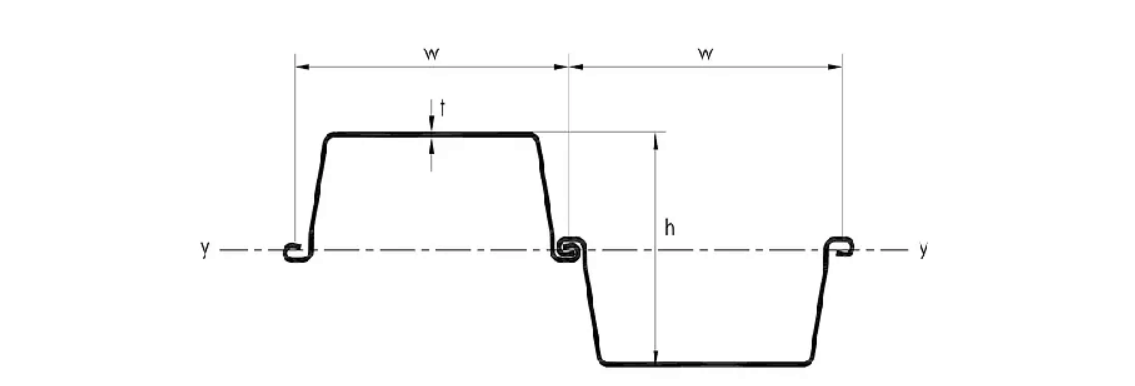

| Width | 400mm/15.75in、600mm/23.62in、750mm/29.53in |

| Height | 100mm/3.94in–225mm/8.86in |

| Thickness | 9.4mm/0.37in–23.5mm/0.92in |

| Length | 6m-24m,9m,12m,15m,18m and custom |

| Type | U-shape steel sheet pile |

| Processing Service | Punching, Cutting |

| Material composition | C≤0.22%, Mn≤1.60%, P≤0.035%, S≤0.035%, conforming to both JIS A5528 and ASTM A328 standards. |

| Mechanical properties | Yield strength ≥ 390 MPa/56.5 ksi; Tensile strength ≥ 540 MPa/78.3 ksi; Elongation ≥ 18% |

| Technique | Cold Formed |

| Dimensions | PU400x100 PU400x125 PU400x150 PU400x170 PU500x200 PU500x225 PU600x130 PU600x180 PU600x210 |

| Interlock types | Larssen locks,cold rolled interlock,hot rolled interlock |

| Certification | JIS A5528, ASTM A328, CE, SGS certification badges |

| Structural Standards | The Americas market is associated with the AISC Design Standard, while the Southeast Asian market is associated with the JIS Basic Engineering Design Standard. |

| Application | Port & wharf construction, bridges, deep foundation pits, water projects, and emergency rescue |

| JIS A5528 Model | ASTM A328 Corresponding Model | Effective Width (mm) | Effective Width (in) | Effective Height (mm) | Effective Height (in) | Web Thickness (mm) |

| U400×100(ASSZ-2) | ASTM A328 Type 2 | 400 | 15.75 | 100 | 3.94 | 10.5 |

| U400×125(ASSZ-3) | ASTM A328 Type 3 | 400 | 15.75 | 125 | 4.92 | 13 |

| U400×170(ASSZ-4) | ASTM A328 Type 4 | 400 | 15.75 | 170 | 6.69 | 15.5 |

| U600×210(ASSZ-4W) | ASTM A328 Type 6 | 600 | 23.62 | 210 | 8.27 | 18 |

| U600×205(Customized) | ASTM A328 Type 6A | 600 | 23.62 | 205 | 8.07 | 10.9 |

| U750×225(ASSZ-6L) | ASTM A328 Type 8 | 750 | 29.53 | 225 | 8.86 | 14.6 |

| Web Thickness (in) | Unit Weight (kg/m) | Unit Weight (lb/ft) | Material (Dual Standard Compatible) | Yield Strength (MPa) | Tensile Strength (MPa) | Applicable Scenarios for the Americas Market | Applicable Scenarios for the Southeast Asian Market |

| 0.41 | 48 | 32.1 | SY390 / Grade 50 | 390 | 540 | Small-Diameter Distribution Pipes for Urban Utilities and City-Scale Irrigation in North America | Irrigation systems: Farmland in Indonesia and the Philippines |

| 0.51 | 60 | 40.2 | SY390 / Grade 50 | 390 | 540 | Foundation Support for Midwestern Homes in the U.S. | Bangkok Urban Drainage Project |

| 0.61 | 76.1 | 51 | SY390 / Grade 55 | 390 | 540 | Gulf Coast flood control levees | Singapore Land Reclamation Project (Small Section) |

| 0.71 | 106.2 | 71.1 | SY390 / Grade 60 | 390 | 540 | Seepage Protection for Houston Port and Texas Oil Shale Dikes | Jakarta Deep-Sea Port Support |

| 0.43 | 76.4 | 51.2 | SY390 / Grade 55 | 390 | 540 | River management in California | Coastal Protection for Ho Chi Minh City Industrial Zone |

| 0.57 | 116.4 | 77.9 | SY390 / Grade 60 | 390 | 540 | Deep Foundation Pits at Vancouver Port, Canada | Malaysia Large-Scale Land Reclamation Project |

Americas: Hot-dip galvanized (ASTM A123, zinc layer: ≥ 85 μm) + 3PE coating (optional), marked with "Environmentally friendly RoHS compliant".

Southeast Asia: Hot-dip galvanized (thickness of zinc layer ≥100μm) + epoxy coal tar coating, highlighting "no rust after 5000 hrs of salt spray test, applicable for tropical marine climate".

-

Design: Yin-yang interlocking, permeability ≤1×10⁻⁷ cm/s

-

Americas: ASTM D5887 compliant

-

Southeast Asia: Resistant to tropical-season groundwater seepage

Steel Selection:

Choose high-quality structural steel (e.g., Q355B, S355GP, GR50) based on mechanical properties

Heating:

Heat billets/slabs to ~1,200°C for malleability.

Hot Rolling:

Shape steel into U-profile with rolling mills.

Cooling:

Cool individually or with tap water sprays until reaching the desired consistency.

Straightening & Cutting:

Verify length and width, then cut to standard or customer-specified size.

Quality Inspection:

Perform dimensional, mechanical and visual examinations.

Surface Treatment (Optional):

Apply paint, zinc plating, or rust protection, as required.

Packaging & Shipping:

Bundle, protect, and load for transport.

- Ports & Quays: Interlocking piles form a strong and stable retaining wall for shorelines as well as docks.

Bridge Engineering: Deep foundation support to increase load capacity and protection against scour.

Underground Parking: Dependable level of lateral support to keep soil from caving in around an excavation.

Water Works: Used for riverbanks, dams, cofferdams -- for safe water control.

Port and Wharf construction

Bridge Engineering

Deep foundation pit support for underground parking lots

Water conservancy projects

- Local Help: Our staff is bilingual (in English and Spanish) and is here to help you.

Stock on hand: Stock can be delivered.

Packing Material : We pack in batches and oil pack for rust prevention.

Dependable Transport: Delivery to site is safe and efficientDependable Transport.

-

Packaging: Bundled with steel straps or wire ropes.

-

End Protection: Wooden blocks or caps on pile ends.

-

Rust Protection: Coated with rust oil or sealed film.

-

Loading & Shipping: Lifted by crane or forklift, securely tied on trucks or in containers.

-

Delivery: Disassembled and neatly stacked on-site for easy access.

Q:Are you able to deliver steel sheet piles to the Americas? Is there any limitation on your delivery?

A: Yes. We provide excellent quality steel sheet piles all over North & Central & South America with professional Spanish speaking assistance for your easy transaction.

Q:How do you pack the steel sheet piles?

A: Bundled with waterproof end-caps, rust prevented, wrapped with plastic woven bags and delivered by truck, flatbed or container right at your site.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506