Prefab Warehouse Steel Structure Workshop Industrial Steel Structure Warehouse

Prefabricated steel structure is steel structure composed of steel materials and is one of the main building structure types. The structure is mainly composed of steel structure, steel columns, steel trusses and other components made of section steel and steel plates, and adopts silanization, pure manganese phosphating, washing and drying, galvanizing and other rust prevention processes.

*Depending on your application, we can design the most economical and durable steel frame system to help you create maximum value for your project.

|

Product name:

|

Steel Building Metal Structure

|

|

Material :

|

Q235B ,Q345B

|

|

Main frame :

|

H-shape steel beam

|

|

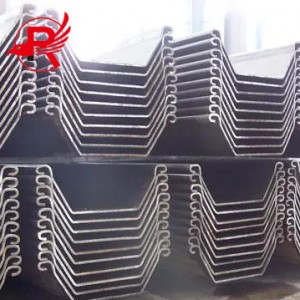

Purlin :

|

C,Z - shape steel purlin

|

|

Roof and wall :

|

1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

|

Door:

|

1.Rolling gate

2.Sliding door

|

|

Window:

|

PVC steel or aluminum alloy

|

|

Down spout :

|

Round pvc pipe

|

|

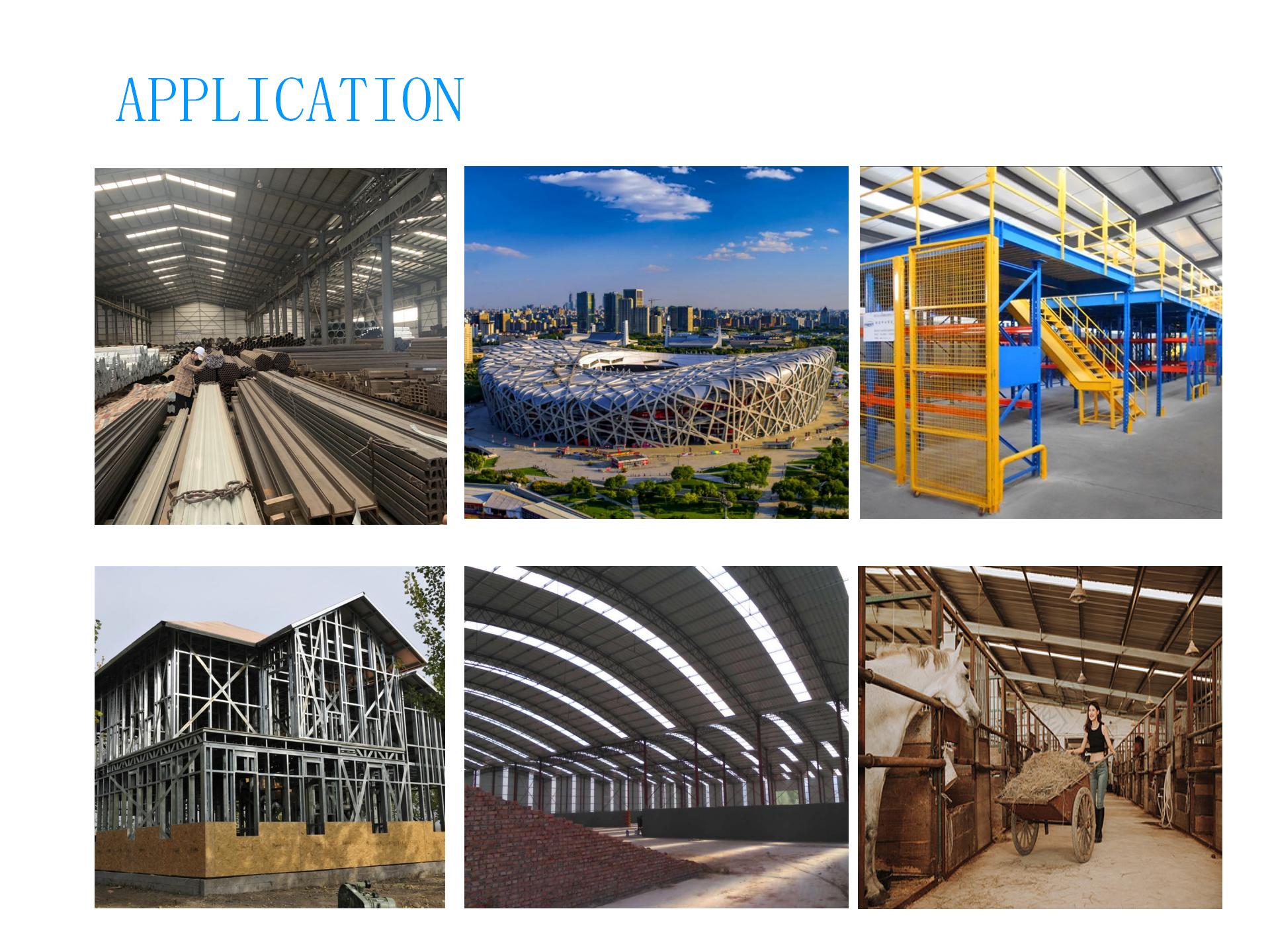

Application :

|

All kinds of industrial workshop ,warehouse ,high-rise building

|

PRODUCT PRODUCTION PROCESS

ADVANTAGE

Unveiling the Advantages of Steel Structures in Construction

In the ever-changing modern construction landscape, steel structures have become a dominant force, offering numerous advantages that meet a wide range of project needs. These advantages are particularly evident for metal building contractors, steel building contractors, steel warehouse builders, steel schools, and steel hotels.

Superior Strength and Durability

Steel, renowned for its high strength-to-weight ratio, is the backbone of strong and durable structures. Metal building contractors often prefer steel because it can withstand immense loads, whether it's heavy machinery in a steel structure warehouse or the dynamic forces a steel school endures during an earthquake. Steel buildings can withstand harsh weather conditions, including strong winds, heavy snow, and torrential rain. For steel hotels located in coastal areas or areas prone to extreme weather, this durability ensures guest safety and maintains the building's integrity over a long service life, minimizing long-term maintenance and repair costs.

Fast Construction Process

Time is of the essence in the construction industry, and steel structures excel in this regard. Metal building contractors can prefabricate steel components with high precision in the factory. These prefabricated components are then transported to the construction site for rapid assembly. For steel warehouse builders, this means significantly shorter construction times compared to traditional construction methods. For steel schools or hotels, this shortened construction time allows for earlier occupancy, allowing students to begin their studies or guests to move in earlier, maximizing return on investment.

Design Flexibility and Adaptability

Steel structures offer architects and designers unparalleled flexibility. During the construction of steel buildings, large, column-free spaces can be easily achieved, allowing for versatility in interior layouts. This is particularly advantageous for steel hotels, allowing for open lobbies, large banquet halls, or flexible meeting spaces tailored to guest needs. For steel schools, spacious classrooms, multi-purpose rooms, and open study areas can be designed without excessive columns, fostering an excellent learning environment. Metal building contractors can work closely with designers to bring even the most complex and innovative designs to life, adapting them to the specific requirements of each project.

Sustainability and Environmental Protection

In an era of growing environmental awareness, steel buildings stand out as a sustainable option. Steel is one of the most recyclable materials in the world. Whether it's a steel warehouse, school, or hotel, at the end of a steel building's lifecycle, its steel components can be recycled and reused, reducing the demand for raw materials and minimizing waste sent to landfills. Steel structure schools and Steel structure hotels can also incorporate energy-efficient designs, such as proper insulation, to lower heating and cooling costs. Metal building contractors are increasingly adopting sustainable construction practices, and steel buildings align perfectly with these goals, making them an environmentally friendly choice for any construction project.

Long-Term Cost Benefits

While the initial cost of steel may seem higher, a thorough analysis reveals its long-term cost benefits. Steel construction takes less time to construct, reducing labor costs and overall project duration. For steel warehouse builders, this means faster operational readiness and earlier revenue generation. Steel's durability also reduces maintenance costs, resulting in lower long-term maintenance expenses. For steel schools and hotels, the longer service life and reduced need for repairs mean significant long-term cost savings. Metal building contractors can leverage the advantages of steel construction to provide clients with cost-effective solutions that deliver value for money without compromising quality.

In short, steel structures offer strength, durability, design flexibility, sustainability, and cost-effectiveness. Whether it’s the expertise of metal building contractors in constructing steel buildings, the functional needs of steel warehouse builders, or the specific demands of steel schools and hotels, steel structures have proven to be the ideal choice for the construction industry, setting new standards for modern building projects.

PRODUCT DETAILS

The construction of Steel Structure Design factory buildings is mainly divided into the following five parts:

1. Embedded components (to stabilize the factory structure)

2. Columns are typically constructed of H-shaped steel or C-shaped steel (typically two C-shaped steels are connected with angle steel).

3. Beams are typically constructed of C-shaped steel and H-shaped steel (the center height is determined by the beam span).

4. Steel purlins: Typically constructed of C-shaped steel and Z-shaped steel.

5. Support points and thrust rods are typically constructed of round steel.

6. There are two types of roof tiles. The first is tiled roof tiles (for color-coated steel roofing). The second is sandwich panels (double-layer color-coated steel sheets sandwiched with polyurethane or rock wool panels). These provide warmth in winter and coolness in summer, while also providing sound insulation and fire resistance.

Application

Industrial buildings:Steel structure building case are often used in factories or warehouses. The prefabricated module, and the processing, manufacturing, transportation and installation are very fast. Moreover, it is light in weight and has strong carrying capacity and shock resistance, which can ensure the safety and stability of the plant. In addition, the steel structure can be disassembled and rebuilt according to needs, with strong flexibility.

Agricultural buildings: Suitable for a variety of agricultural and horticultural crops, they offer advantages such as high light transmittance, high thermal efficiency, energy conservation, environmental protection, and low operating costs. Their all-steel frame support structure and column-free design make the greenhouse more load-bearing, stable, and reliable, and also suitable for animal husbandry.

Public buildings: Many high-rise buildings and stadiums currently utilize steel structures, which effectively protect them from natural disasters such as earthquakes and fires, as well as human damage. Steel structures are corrosion-resistant, heat-resistant, and fire-resistant, making them easy to maintain. Steel structures are typically constructed from high-strength materials, and the steel itself requires no processing equipment, thus saving significant investment.

Residential buildings: The characteristics of steel structures make them lightweight and transparent, enabling the realization of large-span spatial designs and more complex, creative designs at a low cost, energy conservation, and environmental protection.

Equipment platforms: The raw materials used for steel platforms exhibit excellent plastic deformation and ductility, allowing for significant deformation and excellent resistance to driving loads, shortening construction schedules and saving time and manpower. Steel structure engineering machinery has a high level of automation, can carry out systematic production and manufacturing, improve work efficiency, reduce the difficulty coefficient of engineering construction, and is in line with the current characteristics of high-speed operation and environmentally friendly social development.

PRODUCT INSPECTION

Before shipping steel structure products, parts must be inspected to ensure that the quality of the product is intact. Steel components should be inspected for size, shape, surface quality, etc. Damaged or partially non-compliant parts should be replaced or repaired in a timely manner. The quality inspection of steel structure projects includes all specified test and inspection contents of raw materials, welding materials, weldments, fasteners, welds, bolt ball joints, coatings and other materials and projects of steel structures. Sampling testing, steel chemical composition analysis, paint and fire retardant coating testing.

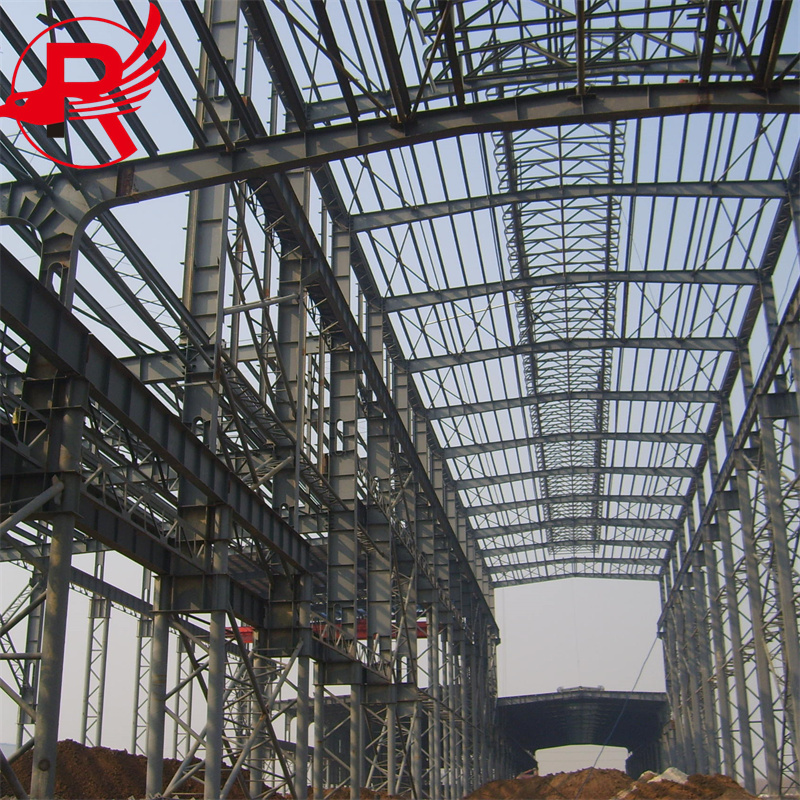

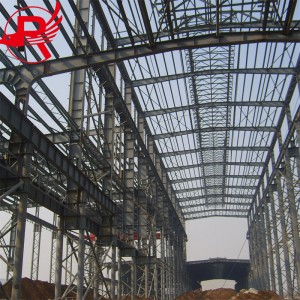

PROJECT

Our company has cooperated with many steel structure company building projects in America, Southeast Asia and other countries.

The steel structure factory building covers an area of approximately 50,000 square meters.

A steel structure factory building primarily consists of a foundation, steel columns, steel beams, a roof, and walls.

Foundation: Embedded foundation components are a crucial component of the factory building structure, primarily responsible for transferring the weight of the factory building to the ground and ensuring its stability.

Steel columns: Steel columns are the main load-bearing components of the factory building and must bear the entire weight. Therefore, they must possess sufficient strength and stability.

Steel beams: Steel beams are also one of the main load-bearing components of the factory building, sharing the weight of the factory building with the steel columns.

Roof: The roof is a crucial component of the factory building and must provide waterproofing, thermal insulation, and heat insulation. It is typically composed of color-coated steel plates, purlins, and supports.

Walls: Another crucial component of the factory building, the walls must provide insulation, soundproofing, and waterproofing. They are typically composed of wall panels, insulation materials, and supports.

PACKAGING AND SHIPPING

Packing: According to your requirements or the most suitable.

Shipping:

Choose the appropriate transportation method: Based on the quantity and weight of the steel structures, select an appropriate transportation method, such as a flatbed truck, container, or ship. Consider factors such as distance, time, cost, and any relevant transportation regulations during transportation.

Use appropriate lifting equipment: When loading and unloading steel structures, use appropriate lifting equipment, such as a crane, forklift, or loader. Ensure that the equipment has sufficient capacity to safely handle the weight of the steel sheet piles.

Secure the load: Secure the packaged steel structure stack to the transport vehicle using strapping, bracing, or other appropriate means to prevent shifting, sliding, or falling during transportation.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structure, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT