Q345b 200*150mm 10r 7r 230 Galvanized Welded Steel H-Beams Steel I Beam Roof Support Beams

Product Detail

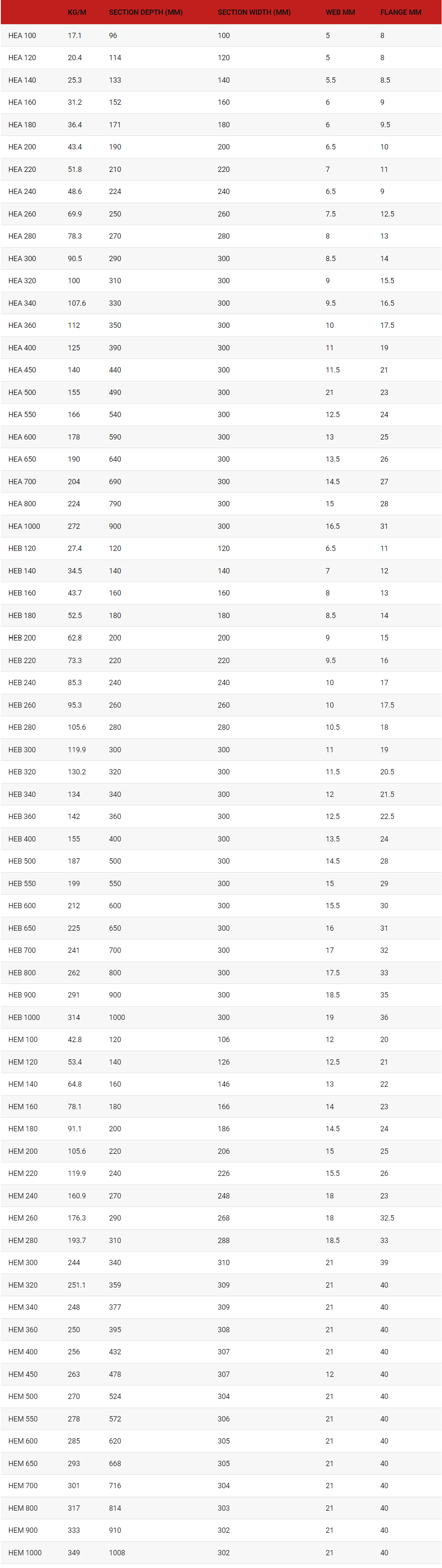

These designations signify different types of IPE beams based on their dimensions and properties:

- HEA (IPN) beams: These are IPE beams with a particularly wide flange width and flange thickness, making them suitable for use in heavy-duty structural applications.

- HEB (IPB) beams: These are IPE beams with a medium flange width and flange thickness, commonly used in construction for various structural purposes.

- HEM beams: These are IPE beams with a particularly deep and narrow flange, providing increased strength and load-carrying capacity.

These beams are designed to provide specific structural capabilities, and the choice of which type to use depends on the requirements of a particular construction project.

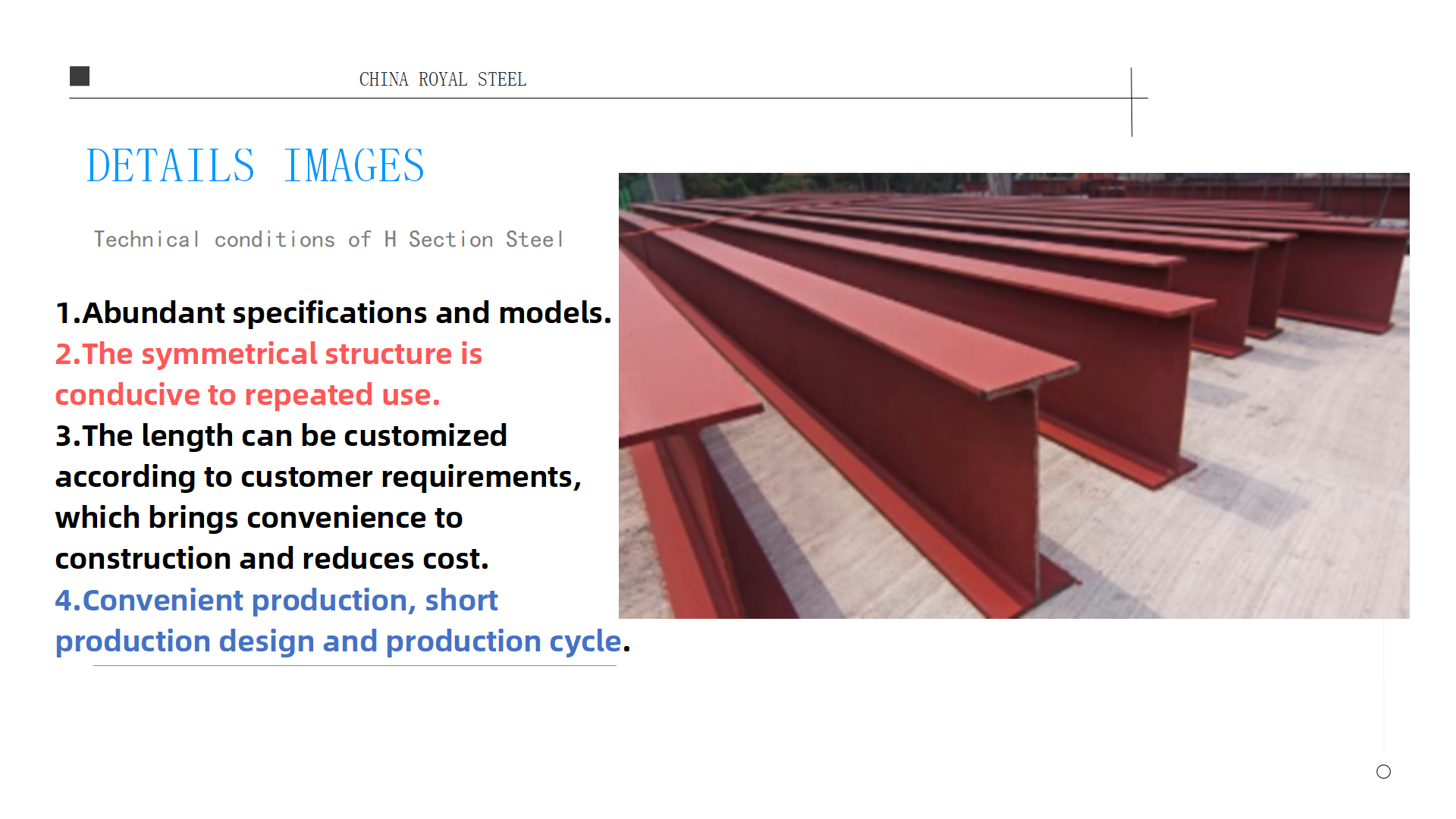

Features

HEA, HEB, and HEM beams are standard European IPE (I-beam) sections used in construction and structural engineering. Here are some key features of each type:

HEA (IPN) beams:

Wide flange width and thickness

Suitable for heavy-duty structural applications

Excellent load-bearing capacity and bending resistance

HEB (IPB) beams:

Moderate flange width and thickness

Versatile and commonly used in a variety of structural applications

Balanced strength and weight

HEM beams:

Extraordinarily deep and narrow flanges

Higher strength and load-bearing capacity

Designed for heavy-duty and high-stress applications

These beams are designed to meet specific structural requirements and are selected based on the intended use and load-bearing demands of the building or structure.

Application

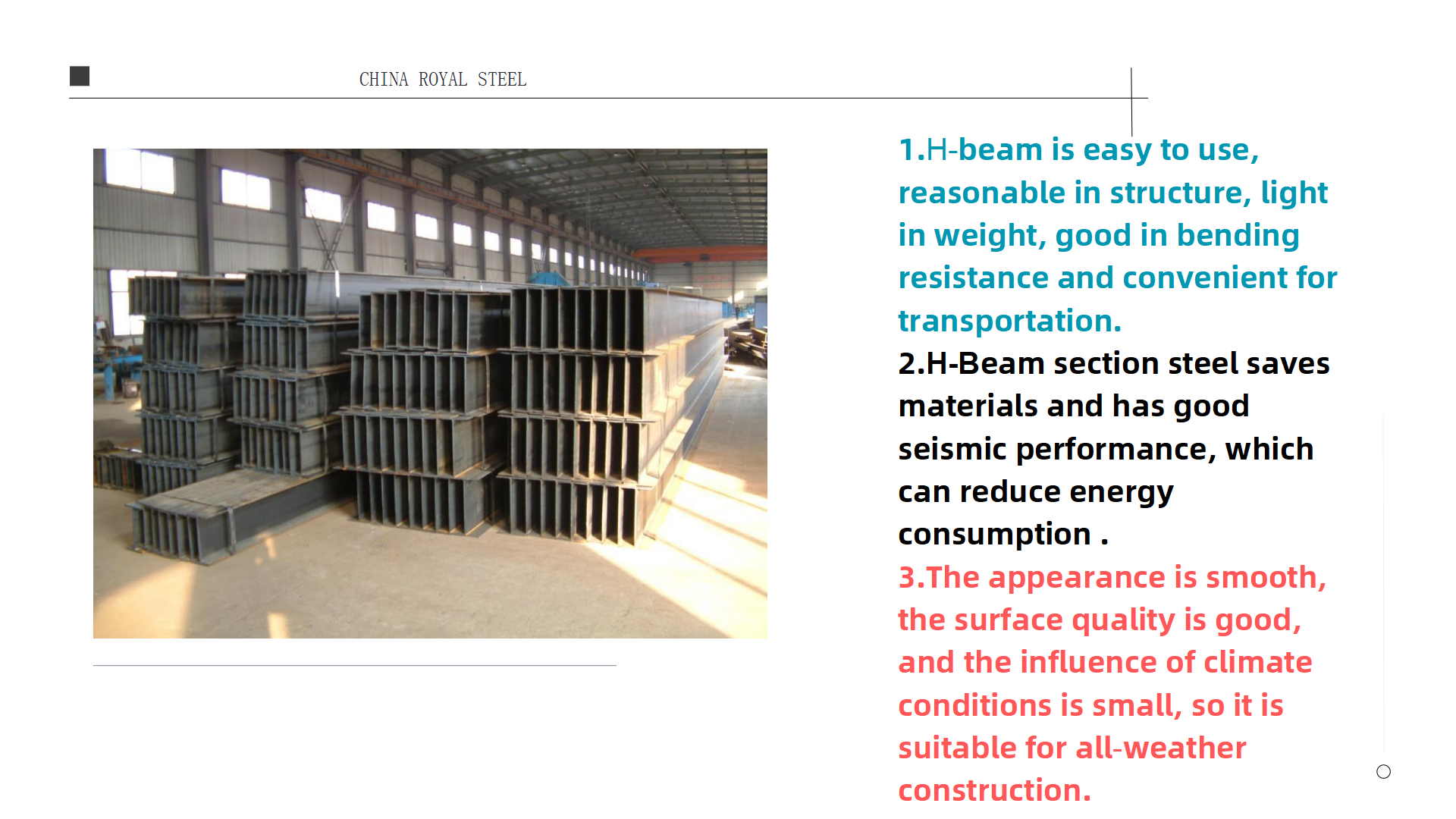

HEA, HEB, HEM and Galvanized H beams have a wide range of applications in the construction and structural engineering industry. Some common uses include:

- Building Construction: These beams are often used in the construction of commercial and industrial buildings to provide structural support for floors, roofs, and other load-bearing elements.

- Bridge Construction: They are utilized in the construction of bridges to support roadway decks and other structural components.

- Industrial Structures: HEA, HEB, and HEM beams are commonly used in the construction of industrial facilities such as warehouses, manufacturing plants, and storage facilities.

- Structural Frameworks: They are used to create structural frameworks for large buildings and infrastructure projects, providing support for walls, cladding, and other structural elements.

- Equipment Support: These beams are used to support heavy machinery and equipment in various industrial settings.

- Infrastructure Projects: HEA, HEB, and HEM beams are also utilized in the construction of infrastructure projects such as tunnels, airports, and power plants.

Overall, these beams are crucial in providing robust and reliable structural support in a wide variety of construction and engineering projects. Their versatility, strength, and load-bearing capacity make them essential components in modern building and infrastructure design.

Packaging & Shipping

Packaging and Protection:

Packaging is crucial to maintaining the quality of ASTM A36 H-beams during transportation and storage. Steel should be securely strapped with high-strength strapping or tying to prevent movement and potential damage. Additionally, measures should be taken to protect the steel from moisture, dust, and other environmental factors. Wrapping the strapping with weather-resistant material, such as plastic or tarpaulin, helps prevent corrosion and rust.

Loading and Securing for Transport:

Care should be taken when loading and securing packaged steel onto the transport vehicle. Using appropriate lifting equipment, such as a forklift or crane, ensures safe and efficient handling. Steel should be evenly distributed and properly aligned to prevent any structural damage during transport. After loading, secure the cargo with appropriate restraints, such as ropes or chains, to ensure stability and prevent movement.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.